I forgot to mention above, the slot on this one is 3/16 wide, for a multiscale (you can see the pencil lines indicating the lie of the bridge on centreline). I use a 3/16 downcut spiral for these and baritones, 1/8 for normal guitars.

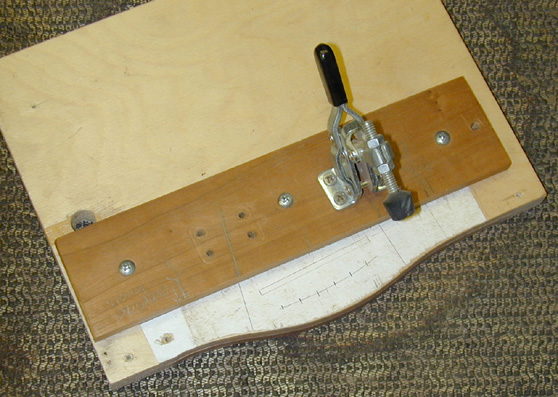

Next up is the pin holes. Its a two part jig, one a simple fence and table with an adjustable stop for the drill press table, the other to hold the bridge, again at the desired angle of your bridge slot (mine angles 1/8 inch over 70mm). The pin holes on my bridges are inline, so the holder jig is set to keep the pin holes equidistant behind the slot, I like them to be 3/8 back on centre. Mark out the line of the holes, and then put marks 35mm out from the centreline of the bridge - these mark you two E string holes, although ony one is needed (you will see why in a sec). Clamp the jig to the table in position so that teh drill bit is in line with the line of the pin holes on the bridge. Set the adjustable stop on the jig such that the sled with the bridge is now ready to drill the high E hole.

now using spacers that have been planed to the pin hole spacing you use (mine are 11mm - 55mm bridge spacing is my std - you can always use additional shims if needed to widen the spacing), place a spacer in between the stop and the sled, and drill the next hole - continue on until all six are done. I made this jig after guitar 3 because it was tough to get the pin holes straight, and evenly spaced - this is pretty much foolproof - a good thing !!!

Now you can bevel the pin holes with a countersink bit (in the same jig), and the bridge is good to get final shaped. I rough cut the wings to thickness on the bandsaw, then sand them to shape by hand on an oscillating drum sander. I also rough shape the 28 radius for the bridge bottom on the drum, then finish that up on a piece of wood that was sanded to 28 ft in the bowl. A quick scrape of the bottom and its all ready to glue on the guitar.

|